zero.9 mm stainless-steel sheet

We produce ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

Other issues through the heat therapy process include the type of furnace, quenching medium and work piece transfer services. Please seek the advice of with the warmth remedy provider for whole steerage on heat therapy of chrome steel grades. We are delighted to help to work with you the particular warmth treatment primarily based in your particular necessities. Technical specifications of DIN 1.4441 austenitic stainless-steel – Chemical composition,mechanical properties from steelmaking,forging,rolling,warmth remedy,cold working.We also possess superior precision machining equipments for further processing.

BIOVAL® is the registered trademark for these special steels characterised by high biocompatibility, corrosion resistance, and wonderful standards of micro-cleanliness necessary for the secure manufacture of orthopaedic, spinal and dental implants as well as osteosynthesis. Beyond eradicating impurities, this course of, together with the unique nickel and chromium content of 316, tends to facilitate the formation of the floor chromium oxide layer that makes stainless steel corrosion resistant. There is a few belief that T-316 LVM types a extra substantial surface layer, and that this performs a robust function in defending the host physique from reactions to the nickel content of the fabric. Type 316L is an improved corrosion resistant Chrome-Nickel metal alloy with a excessive content material of Molybdenum. When heat treating a stainless the hardening temperatures, including price of heating, cooling and soaking times will range as a result of a number of elements similar to the form and dimension of every component.

The common content of these elements is subsequently defined, separated by hyphens in the same descending sequence. The alloys have extremely-high energy, superior toughness characteristics and weldability. Typically, these alloys are used in aerospace applications, equipment and tooling and ordnance parts and fasteners.

Stock Thickness: 0.1-200.0mm

Production thickness: 0.5.0-200mm

Width: 600-3900mm

Length: 1000-12000mm

Grade:

200 series: 201,202

300 series: 301,304,304L,304H,309,309S,310S,316L,316Ti,321,321H,330

400 series: 409,409l,410,420J1,420J2,430,436,439,440A/B/C

Duplex: 329,2205,2507,904L,2304

Surface: No.1,1D,2D,2B,NO.4/4K/hairline,satin,6k,BA,mirror/8K

- The material is non-magnetic, even after a number of chilly forming operations.

- Type 316L Stainless Steel is an improved corrosion resistant Chrome-Nickel steel alloy with a excessive content material of Molybdenum.

- It is austenitic Stainless Steel for implants, with high corrosion resistance, based on ISO 5832/1, F-138 Vacuum soften grade (VAR).

- Type 316L isn’t a typical freemachining grade and therefore not really helpful for troublesome excessive velocity machining.

Implant metal with improved corrosion resistance compared to AISI 316L. The numeric designation deriving from the out of date DIN normal contains 5 digits and commences with 1.4; the third digit relates to a certain sort of metal family and displays the chemical composition. Maraging steels are iron-nickel alloys with absence of carbon and have metals corresponding to molybdenum, cobalt, titanium and aluminum. ECONOXX.com offers patrons a brand new and uncomplicated procurement channel, which additionally consists of small portions and supplies in special alloys at beneficial conditions. The marking begins with the letter “X”, followed by the carbon content x 100, then the chemical symbols for the alloy parts in descending sequence based on their content.

The addition of molybdenum improves resistance to chloride, sulphuric acid and other organic acids. This is the explanation that stainless-steel 1.4435, 316L, X2CrNiMo is commonly the only option for watch making purposes.

Stainless Steels

316LVM (low carbon vacumm soften) chrome steel, thought to be a medical grade, this chrome steel is vacuum melted to achieve high ranges of purity and cleanliness. It has glorious resistance to both general and intergranular corrosion, and pitting and crevice corrosion.

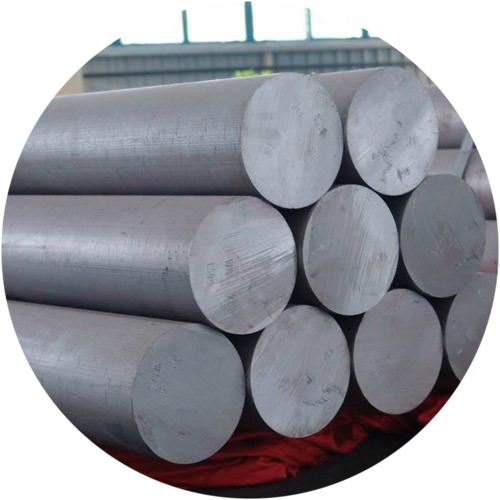

Aisi 420c , En 1.4034 , Din X46cr13 Stainless Steel Wire And Round Bar

316LVM Stainless Steel is our mostly bought medical stainless-steel. Breaking down the name, this is a low-carbon model of 316 that has been vacuum arc remelted to scale back impurities.

We have thousands tons stock of stainless steel sheet and coil with various size and grade,mainly include austenitic stainless steel, martens stainless steel (including precipitation hardened stainless steel sheet & coil), ferritic stainless steel, and duplex stainless steel.

Characteristics of Stainless Steel Sheet and Plate:

High corrosion resistance

High strength

High toughness and impact resistance

Temperature resistance

High workability, including machining, stamping, fabricating and welding

Smooth surface finish that can be easily clean